Another Big Bang for Lithium Universe: Hatch opens itself for James Bay plant design study

Hatch has been commissioned to design Lithium Universe’s James Bay lithium carbonate plant. Via Getty Images.

- Galaxy Resources’ Jiangsu plant designer Hatch will take on the design study of Lithium Universe’s proposed 16,000tpa lithium carbonate plant

- Hatch is a global leader in the design of lithium refineries

- The Lithium Universe team has had great success in building lithium carbonate plants in both China and Australia

In a further cosmological shift for Lithium Universe, another ex-Galaxy business – plant designer Hatch – is headed to James Bay, Canada to design its lithium carbonate processing facility.

Global engineering behemoth Hatch has been signed on to undertake the vital engineering study for the design of Lithium Universe’s (ASX:LU7) multi-purpose battery-grade lithium carbonate (Li2O3) refinery – part of its proposed Québec Lithium Processing Hub (QLPH).

The first part of the study will be to determine the ideal location of the lithium refinery, and, LU7 says, “will aim to define the process and non-process infrastructure requirements for a 16,000tpa lithium carbonate refinery, as well as the definitive estimated capital and operating costs”.

Lithium focus

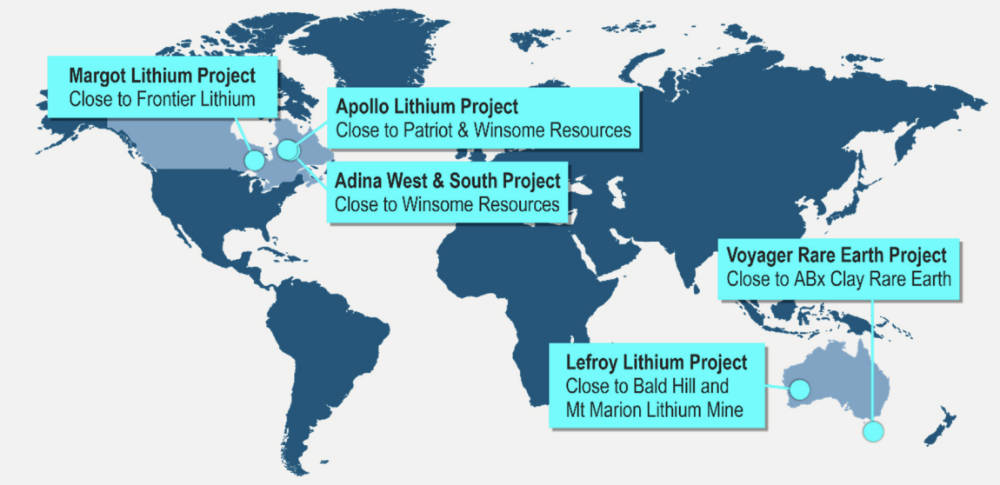

LU7 burst onto the ASX back in August after a $4.5m IPO and has tenure in both Australia and Canada – regions where the team has vast experience in developing lithium projects.

Near to the proposed hub, LU7’s primary focus is on its 240km2 Apollo project, 29km southeast of Patriot Battery Metals’ (ASX:PMT) huge 109.2Mt @ 1.42% Li2O Corvette lithium project.

It’s also staked ground at Margot Lake in Ontario’s Red Lake district, a mere 16km from Frontier Lithium’s 9.9Mt @ 2% Li2O PAK deposit and 18km away from its 18.8Mt @ 1.52% Spark deposit.

Elsewhere in Canada it has the Adina West and South projects, and in Australia, the Lefroy lithium project in WA and the Voyager rare earth project in Tasmania.

Together again

With a board, technical team and contractors that all worked on Galaxy’s successful Mt Cattlin lithium mine (which, now run by Allkem (ASX:AKE), produces 137,000tpa of spodumene concentrate), Hatch’s inclusion to LU7’s vision brings further expertise on board.

The design will include the use of conventional kiln conversion of spodumene, sulphuric acid sulphation and leaching, impurity removal and final purification to battery-grade quality lithium carbonate, similar to that of Hatch’s design of the Jiangsu Li2O3 plant.

LU7 chair Iggy Tan and non-executive director Dr Jingyuan Liu previously worked with Hatch on the design, construction and commissioning of the Jiangsu plant which was sold to China’s Sichuan Tianqi Lithium in 2014 for a cool $132m.

Tan says the overall mission is to build a multi-purpose standalone concentrator feeding a battery-grade lithium carbonate plant.

“Exactly what we’ve built in Jiangsu – what does it take to build that same plant in northern Québec, what is the current price, and by having that information we can then start to look at possible funding options,” Tan said.

“Part of the strategy is also we want to talk to some of the juniors around us to see whether we can buy run-of-mine material that will feed our concentrator.

“So we help all the juniors around us develop their mines by having a five-year offtake for the ROM material that allows them to develop their mines and then we use that as the feed for our concentrator.”

Lithium carbonate

Lithium Universe says it made the deliberate choice to focus on lithium carbonate rather than lithium hydroxide due to its widespread use in the fast-growing Lithium Iron Phosphate (LFP) batteries.

LFP batteries are increasingly used in EV applications due to their lower costs, longer shelf life, and superior stability compared with lithium hydroxide.

With LU7’s previous experience in the Li2O3 processing realm, it’s a no-brainer for them, and Tan says LU7 “welcomes the opportunity to work with Hatch once again”.

“We have got the same team back together and their role is to replicate the success of their previous experience at the Jiangsu lithium carbonate refinery,” he says.

“Today that plant is considered to be a global benchmark for lithium refineries and is renowned for producing the highest-quality battery-grade lithium carbonate worldwide.

“With this remarkable expertise and experience, Lithium Universe considers that it can replicate the same level of success in Québec, Canada.”

This article was developed in collaboration with Lithium Universe, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.