Trajan delivering precision to global science, one component at a time

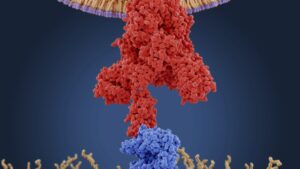

Trajan components and consumables work to underpin the integrity of analytical results. Pic via Getty Images.

- Trajan ensures accuracy of laboratory results worldwide with its components and consumables

- Company has grown five-fold in past decade with a network with seven manufacturing sites across the US, Australia, Europe and Malaysia, and operations in Australia (HQ), the US, Asia, and Europe

- Trajan produces best-in-class components and consumables to underpin integrity of analytical results

Special Report: The components and consumables business of Melbourne-headquartered global analytical science and device company Trajan Group Holdings is delivering precision-engineered solutions that ensure accuracy and reliability of laboratory results worldwide.

Trajan Group Holdings (ASX:TRJ) has three segments to its business – capital equipment, components and consumables, and disruptive technologies supporting new innovation and product development.

“Components and consumables accounts for around two-thirds of Trajan’s total revenue or just north of $100 million per year,” CEO and managing director Stephen Tomisich said.

“The components and consumables are in many ways the financial engine of Trajan with that recurring revenue enabling us to build the business, even before IPO, and fund growth through the constant cashflow.”

Trajan was founded in 2011 by Tomisich and his wife Angela, who both have backgrounds in applied science, and made its IPO in 2021. The company has since doubled its financial scale through strong organic and acquired growth.

Trajan delivers precision to global science

Trajan’s components and consumables have become important for a range of vital applications from clinical diagnostics and pharmaceutical research to food safety and environmental monitoring.

Around 40% of Trajan’s components and consumables are used in gas chromatography, a laboratory technique that separates and analyses compounds in a sample by vaporising them.

“Gas chromatography is critical for detecting and measuring volatile substances across applications in clinical diagnostics, pharmaceuticals, food safety and environmental testing,” Tomisich said.

“It’s about precision tubes, connection devices and specialised sealing materials – so a broad portfolio related to gas chromatography.”

Around 30% is made up of precision injection devices, commonly referred to as syringes.

“As soon as you use the word syringes people have an image of patients and injections and plastic disposable devices and ours couldn’t be more different,” Tomisich said.

“They look like a syringe but they’re used to accurately deliver volumes of liquid into analytical instrumentation, down to the nanolitre so they’re very precise products.”

The remainder of Trajan’s components and consumables business falls under precision fluidics — enabling controlled, accurate handling of small liquid volumes in analytical and diagnostic workflows.

“For example, we supply some of the precision tubing which goes into the world’s nano fluidic systems which are used to isolate, manipulate, and detect individual biomolecules such as DNA, RNA, and proteins,” the CEO said.

“This is tubing where the inside diameter is thinner than a human hair and sometimes very difficult to see with the human eye. They are very difficult to manufacture, and Trajan is one of very few capable of precision manufacturing.”

The technologies also support mass spectrometry by ensuring samples are delivered into the instrument with precision.

Trajan’s consumables business also covers sample transport including supplying vials, caps and other essential components widely used in anatomical pathology labs.

“It is quite a diverse and very broad range of products which make up our components and consumables business,” Tomisich said.

Ensuring quality of analytical results

He said that when Trajan was developing its long-term strategy, it recognised that any component or consumable in contact with a sample could impact the quality of the analytical result.

“That was coupled with an observation that the analytical instruments themselves had become more robust, reliable and in particular sensitive.

“Due to their improved measurement power, they’re able to reveal the variation which can be caused by the bits and pieces or so-called plumbing used to get the sample into the instrument to get measured.”

Trajan has focused on producing best-practice components and consumables to underpin the integrity of analytical results through two key factors.

The first Tomisich explained was “reproducible, precision fabrication on scale”, meaning Trajan’s components must have consistent physical form and quality across large production volumes to ensure reliable analytical results.

Previously many of these products were made by companies around the world by hand with craftsmen.

“They were very talented and skilled individuals but unfortunately any time human hands touch something you cause variation so Monday’s product might not be the same as Tuesday’s,” he said.

Trajan has a network of seven global manufacturing sites spanning Australia, Europe, Malaysia and the US, which Tomisich said was a key advantage over competitors.

“We’ve intentionally invested in infrastructure in Melbourne and other places around the Trajan world that have been custom designed and built to produce these products on scale.

“Our components and consumables will always be the same and consistency is king in delivering these sorts of products.”

The second factor in producing best-in-class components and consumables, he said, was ensuring chemical inertness of the surface the sample contacted to ensure the interaction didn’t compromise its integrity.

Solving customer problems with diversity for growth

Tomisich said Trajan constantly worked on trying to solve customer problems to broaden its product range. “It’s also about listening to our industry partners as well.”

Trajan has made numerous acquisitions, developed collaborations and partnerships as part of its growth and commitment to delivering best practice solutions.

“One of the things Trajan does very well is we sit down with the captains of the industry – major multinationals who make the instrument platforms,” the CEO said.

“We try to understand the new problems they’re trying to solve and what role our components and consumables can play in the solutions.”

Trajan has grown five-fold over the past decade, with many of its original equipment manufacturer (OEM) customers still accounting for the same share of sales as they did 10 years ago.

“They’ve come along with us on that journey driven by the fact that as we establish ourselves as a reliable partner, it helps them gain market share with how they go to market with our products,” he said.

“As we develop or have new products come into the portfolio through acquisitions, we become a supplier of those to our customers as well.

“There’s been examples where our OEM customers have pointed us to other suppliers to acquire so we could bring our science, engineering and scalability to products still in labour intensive production processes.”

Tomisich said diversity of its components and consumables portfolio, customers, geographies and applications meant it had predictable and resilient growth.

“There is a level of reassurance with Trajan that the underlying part of the business continues on and is incredibly resilient, and it’s strategically been built that way,” he added.

This article was developed in collaboration with Trajan, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.