Nanollose teams with Paradise Textiles to produce fabric using its Forest-Friendly Nullarbor fibre

Nanollose says Paradise Textiles has produced 200 yards of high-quality fabrics using Nullarbor-20 tree-free fibre. Pic via Getty Images.

High-quality fabrics using Nanollose’s Forest-Friendly, Nullarbor staple fibre has been produced as the company works to improve fashion sustainability.

Australia-based biomaterial technology company Nanollose (ASX:NC6) has announced 200 yards of high-quality fabrics incorporating Nullarbor-20™ fibre have been produced by Paradise Textiles Limited (Paradise).

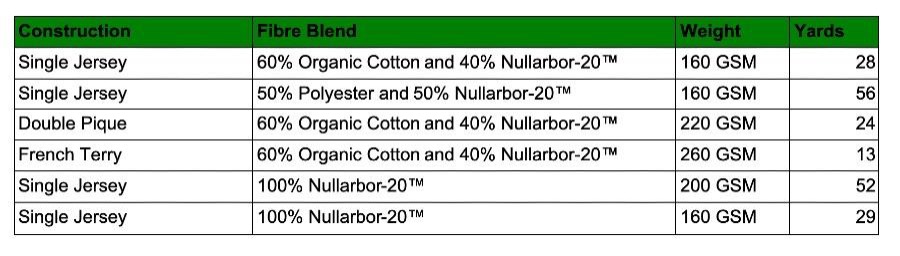

Paradise successfully converted the 135kg of Nullarbor-20 staple fibre into several types of yarn and subsequently knitted these yarns into six fabric varieties, including four Single Jerseys, a French Terry, and a Double Pique.

Different fabric textures for French Terry, Single Jersey and Double Pique (left to right) Source: Nanollose

Several of the fabrics were blends of Nullarbor-20 with other fibres to produce fabrics known to be in demand by potential partners and the industry generally.

Half the fabric has been dyed black and the other half left its natural white.

Details of the fabrics produced

The 135kg of Nullarbor-20 staple fibre used by Paradise to make the fabrics was part of the 260kg batch produced by Birla Cellulose at their pilot facilities earlier this year.

Testing confirms high-quality fabrics

In addition to manufacturing the fabrics, Paradise undertook extensive testing on the finished product.

Shrinking, colour fastness, and pilling were among tests conducted with results indicating that the fabrics are of a high quality.

Paradise has also indicated that the Nullarbor-20 fibre performed extremely well in the production process.

Given the positive results both Nanollose and Paradise will continue the collaboration, first announced in May.

Paradise is the technology first, material science, innovation hub of award-winning apparel manufacturer Alpine Group.

Nullarbor a preferred fibre for Paradise Textiles

Nanollose Executive Chairman Dr Wayne Best said the company was delighted with the quality and diversity of the fabrics produced by Paradise Textiles.

“The production process highlighted the versatility of Nullarbor-20 fibre, as well as how the finished fibres hold up against stringent testing protocols required for garment manufacture,” he said.

He said Paradise had been a tremendous partner to work with throughout the process.

“Their communications and commitment to the project have been outstanding and we look forward to working with them to develop additional materials going forward,” he said.

Paradise Textiles and Alpine Group co-founder and chairman, Ashok Mahtani said the company was excited to partner with Nanollose on an innovation that is very meaningful to the industry.

Mahtani said Paradise has committed to bringing tree-free man-made cellulosic fibres (MMCF) solutions to the apparel and footwear industry, publicly pledging that 75% of all MMCF will be derived from tree-free sources by 2030.

“To get there, we need the supply, and Nullarbor is a preferred fibre with the potential to match that scale,” he said.

“Through rigorous R&D tests our team has validated that Nullarbor-20 is ready for wide adoption.

“We look forward to our continued collaboration with Nanollose and ultimately, making a material difference.”

Nanollose launched a garment designed by Lee Mathews, an Australian womenswear fashion designer, in collaboration with leading man-made cellulosic fibre manufacturer Birla Cellulose at the Global Fashion Summit in Copenhagen mid-year.

The company has entered a series of collaborations globally as it moves to get its Tree-Free and Forest-Friendly Nullarbor fibres to market.

This article was developed in collaboration with Nanollose, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.