Bojun steps up mandarin vinegar production, investigates drying peel

Pic: Rommel Gonzalez / EyeEm / EyeEm via Getty Images

Mandarin cider vinegar maker Bojun will soon be making as much as 30,000 tonnes of the beverage a year.

The company (ASX:BAH) just bought a new million-dollar bottled fruit vinegar production line, which is set to be installed and commissioned in coming months.

But that’s not the only obscure citrus product the company has in mind.

Bojun has also built a new “peel processing” workroom to turn previously discarded peels into sellable dried food products.

They say the new facility has improved the overall utilisation rate of the fruit and will generate additional revenue – at a cost of about $250,000.

Citrus peel – known as Chenpi or ‘preserved peel’ – is used as traditional seasoning in Chinese cooking and traditional medicine.

The innovative mandarin processing methods have come from research and development programs conducted with local universities.

Bojun spent $300,000 to design a special temperature control system for its fruit wine fermentation and a further $930,000 to improve the planting and cultivation of its trees.

Bojun told investors it would invest in research in Australia. The project has attracted attention from the NSW Department of Primary Industries (perhaps facilitated by former NSW politician, now BAH chairman Andrew Stoner).

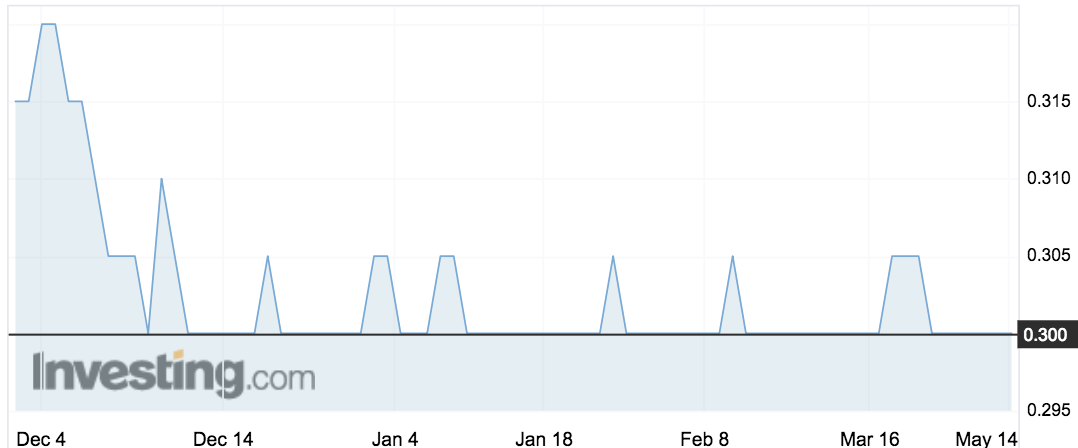

The shares have moved little since listing in December at 30c — today the stock opened at its issue price.

Apple cider vinegar is often touted for its health benefits, but Bojun believes it is the first brewer to ferment mandarins for this purpose. Bojun owns a patent for the process in China and plans to register trademarks across the globe.

It might be a while before the characteristic vinegar drink is available in Australia though.

Bojun is targeting markets such as Korea and Japan where locals apparently have a taste for the drink.

Mandarins are now sourced from China. Bojun owns orchards in Nanfeng, a town in the south-central province of Jianxi.

Mr Stoner — who quit politics in 2014 to spend more time with his family — is keen on adding to production with an Australian facility, acknowledging the value of “Australian Made”.

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.