Sparc’s game changing joint venture could create low cost ‘ultra green hydrogen’ without electricity

Pic: Matthias Kulka / The Image Bank via Getty Images

One of the core technologies in the fight against climate change is green hydrogen, clean-burning H2 gas produced by sending an electrical pulse – generated by wind or solar power – through water.

While it has support from the upper echelons of the business world, a major roadblock to the production process is its cost relative to current forms of hydrogen production, which use fossil fuels as a feedstock.

But what if you never had to produce electricity at all?

Sparc Technologies (ASX:SPN) today announced it will link up with the University of Adelaide to progress an Australian made “ultra green hydrogen” technology that does not require electrolysis to extract the lightweight gas from water.

Without the costs of generating renewable energy, the project partners are targeting a commercial scale technology to help meet the $2/kg target widely regarded as the mark green hydrogen needs to limbo under to be cost competitive.

Game changing technology

Marking a big move for the graphene technologist into green energy, Sparc Technologies believes the globally significant project can be a game changer for the hydrogen industry, expected to be worth up to US$12 trillion globally by 2050.

“Green hydrogen energy has often been touted as being able to provide base load electricity, however it has struggled to compete economically against conventional fossil fuel base load electricity,” Sparc Technologies executive chairman Stephen Hunt said.

“This globally significant project offers a realistic pathway to achieving economically feasible green hydrogen energy and to advancing industry to net-zero.”

Hunt said Sparc was looking at applying its existing graphene expertise in the green energy space as well, developing graphene coatings to be used in conjunction with a catalyst in the production process.

“Developing additional graphene applications in the ultra-green hydrogen energy space is also a very important growth opportunity for Sparc.”

The process

The ultra green hydrogen process developed by University of Adelaideand Flinders University.

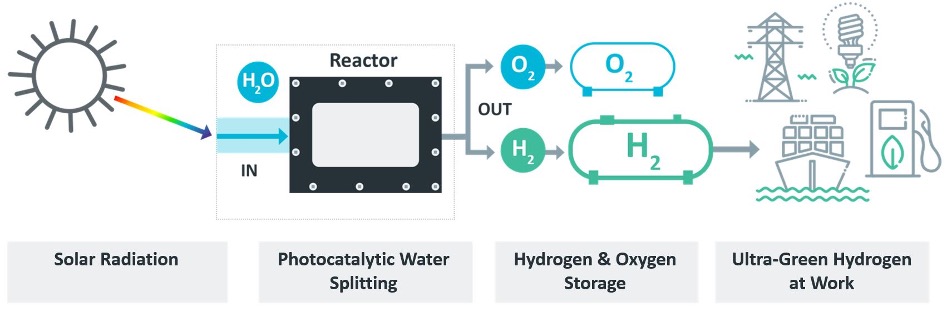

It involves the use of photocatalysis, the acceleration of a photoreaction in the presence of a catalyst.

In catalysed photolysis, light is absorbed by an adsorbed substrate. In photogenerated catalysis, the photocatalytic activity depends on the ability of the catalyst to create electron–hole pairs, which generate free radicals like hydrogen to be able to undergo secondary reactions.

Photocatalytic water splitting is an artificial photosynthesis process with photocatalysis in a photoelectrochemical cell used for the dissociation of water into its constituent parts.

In other words, only light energy and a catalyst could be needed to split water into oxygen and hydrogen, which has emerged as the likely replacement for gas and diesel in heavy industry and long haul vehicles.

On top of the potential cost savings, without the footprint associated with massive scale wind and solar farms, the technology can also be adopted remotely at the site of use, reducing the development and transmission costs of electricity and transport.

So far there has been plenty of research into the topic, but no technology has been commercialised.

Sparc and the University of Adelaide are looking to change that.

Joint Venture terms

The Australian Solar Thermal Research Institute, the UoA and Flinders University have invested $2.5m to date over a 5-year period into the research.

A provisional patent was applied for in April 2021, and research has already been undertaken on the use of graphene to be used in conjunction with the photocatalyst, where the prototype demonstrated a significant increase in hydrogen production with certain temperatures.

Under the JV the University of Adelaide will retain 28% of the JV with Sparc taking a 72% share.

Sparc will issue 3 million shares to UoA and put $4.75 million into the project over the next 4.5 years, including $2m for the 2.5 year first stage, $2.5m over the second stage and $250,000 to be paid to UoA for operations set up and a scholarship.

“This is an exciting opportunity for us to combine with the University of Adelaide, reconfirming our commitment to seeking out and developing new green technologies that include Sparc graphene technology,” Sparc managing director Mike Bartels said.

“The hydrogen production process we are developing is world leading, cutting-edge in that it does not require electrolysis as the means of producing hydrogen.

“Employing patented technology, hydrogen will be produced by a process known as photocatalysis and most importantly this project is not just about delivering green hydrogen – we are confident that this process will deliver ultra-green hydrogen at the low end of the cost curve.

UoA Executive Director, Innovation & Commercial, Dr Stephen Rodda said: “This joint venture is a perfect example of the University of Adelaide’s internationally regarded research being brought to a commercial outcome, which we hope will have benefits for industry and the community.

“We are proud to be the leading university involved in this venture, applying our research and innovation in responding to one of the great challenges of our times: the development of green energy solutions for our planet.”

Placement to fund JV

Sparc has received firm commitments to raise $2.8 million before costs, via a placement of 4 million shares at 70c a pop.

The placement, conducted at a 21.8% discount to Sparc’s last traded price of 89.5c, was conducted by Discovery Capital Partners and Westar.

This article was developed in collaboration with Sparc Technologies, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.