Altech Batteries’ silicon anode tech captures the interest of a leading battery manufacturer

Altech Batteries’ Silumina Anodes technology is being evaluated by a leading battery manufacturer. Pic: Getty Images

- Leading EV battery maker signs NDA after seeing performance of Altech’s silicon coating tech

- Samples sent for evaluation with testing to be carried out on manufacturer provided graphite samples

- Latest tests show 83% capacity retention after 1000 cycles, confirming durability and real-world commercial potential

Special Report: Altech Batteries’ proprietary technology for enhancing lithium-ion battery anodes with silicon has received clear validation after capturing the attention of a leading global electric vehicle battery manufacturer.

The unnamed Battery Group expressed strong interest in the company’s Silumina Anodes technology that incorporates silicon into battery anodes, improving performance while maintaining long-term stability.

During preliminary discussions, the Battery Group team noted it had not previously seen silicon additions deliver meaningful performance improvements at low percentages due to the challenges posed by expansion-related degradation, unstable solid-electrolyte interphase formation and rapid cycle-life fade.

That is until they encountered Altech Batteries’ (ASX:ATC) coated silicon technology, which the company described as “particularly noteworthy” due to its ability to deliver strong performance with only modest silicon loading.

The Battery Group also acknowledged that very few material suppliers globally were producing silicon additives with this level of stability, consistency and real-world applicability.

As such, the unsolicited approach by the battery manufacturer has led to the execution of a mutual non-disclosure agreement (NDA) to enable the confidential technical exchange and evaluation of materials.

Under this collaboration, the company has prepared and supplied Silumina Anodes samples developed under the leadership of chief technical officer Dr Jingyuan Lui to Battery Group for formal testing in their advanced battery-evaluation laboratories in China.

Battery Group has also requested that ATC undertake coating trials on their supplied graphite material to assess the performance impact of integrating Altech’s proprietary alumina technology directly onto their own anode substrate.

These coated graphite samples will be benchmarked against their internal standards, providing a direct comparison of how ATC’s technology enhances their preferred graphite formulations.

“This engagement from the world’s largest battery manufacturer is a powerful validation of our Silumina Anodes technology,” ATC managing director Iggy Tan said.

“Their early feedback, particularly noting they have not seen silicon additions perform this effectively at such low levels, reinforces the significance of our breakthrough.

“We are excited to advance this collaboration under the NDA and look forward to demonstrating how Altech’s coating technology can further enhance their graphite and anode performance.”

Watch: Altech flexes impressively reliable battery tech

Performance improvements

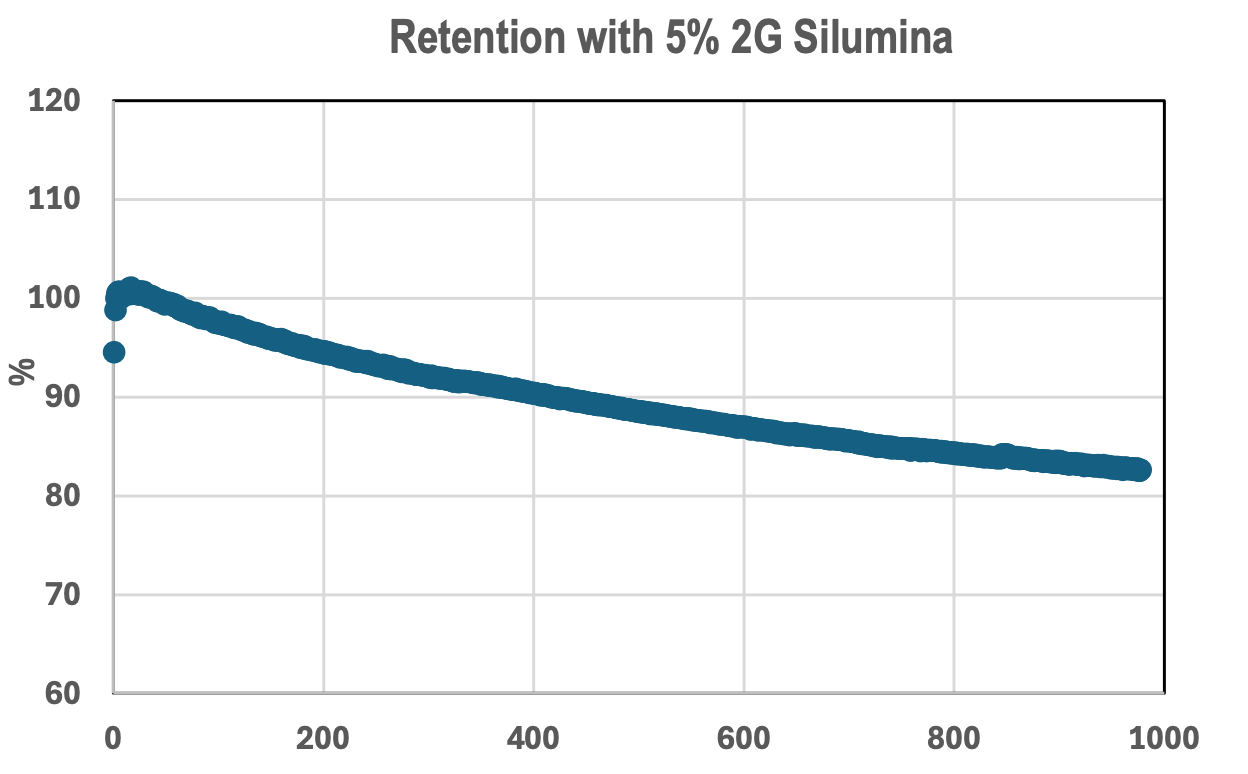

Highlighting the continued work the company has been putting into the technology, it noted that latest testing had demonstrated impressive 83% capacity retention after an industry standard 1000 charge-discharge cycles with a 5% Silumina Anodes addition to a standard graphite anode.

This follows on from it demonstrating 88.5% capacity retention after 500 charge-discharge cycles in October 2025.

ATC said this represented a significant milestone for the technology as it confirmed its durability and real-world commercial potential.

Importantly, such cycle-life performance places Altech’s material at the forefront of next-generation silicon-enhanced anode technologies, strengthening its position in the rapidly evolving global battery materials market.

Silicon has long been recognised to be capable of greatly increasing the energy density of lithium-ion batteries as it can theoretically store up to 10 times as many lithium ions as graphite.

However, its potential has long been limited because the adsorption of silicon ions is accompanied by swelling of up to 300%, leading to mechanical stress, particle fracture and rapid capacity loss.

ATC’s technology overcomes the silicon expansion issue by transforming irregular silicon particles into perfectly rounded, alumina-coated spheres that integrate seamlessly within graphite anodes.

When blended into the graphite anode matrix, the spherical Silumina particles naturally occupy microscopic voids, where they can expand and contract freely during cycling without damaging the surrounding structure.

In testing, battery cells containing 5% silicon in the anodes recorded a ~40% increase in capacity over graphite-only anodes.

A 40-50% increase in anode capacity typically equates to a 20-25% gain in total cell energy, depending on cathode pairing.

This article was developed in collaboration with Altech Batteries, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.

Related Topics

UNLOCK INSIGHTS

Discover the untold stories of emerging ASX stocks.

Daily news and expert analysis, it's free to subscribe.

By proceeding, you confirm you understand that we handle personal information in accordance with our Privacy Policy.