Hazer is a step closer to proving its hydrogen tech works in the real world

Tech

Tech

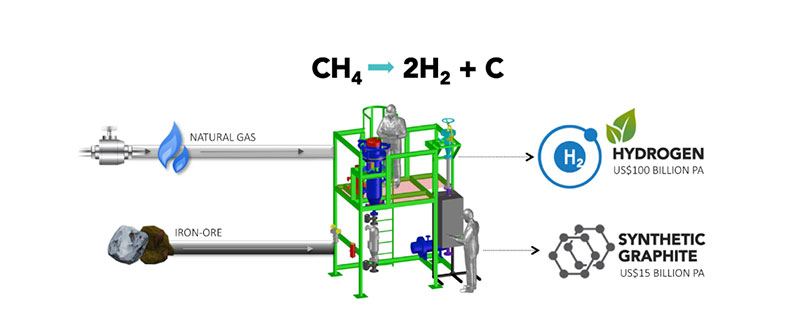

Hazer (SX:HZR) has a potentially ground-breaking technology for producing hydrogen and graphite from gas and iron ore.

The hydrogen energy market is small but growing; and it has the backing of major players in politics, oil and gas, infrastructure, car making, and petroleum.

Now, after years of development, Hazer has reached the all-important ‘does it work in the real world?’ phase.

Following the success of a pilot (smaller) stage in 2018, the company’s focus turned to developing a commercial demonstration plant to validate the technology at scale.

Here it is:

Today, Hazer announced a non-binding agreement with the Water Corporation to develop a 100-tonne-per-annum, low-emission hydrogen production facility at the Woodman Point wastewater treatment plant in WA.

Water Corporation is the state’s #1 supplier of water, wastewater and drainage services.

If built, this would be Hazer’s all-important commercial demonstration plant — proof that the tech can operate cost effectively, day-in day-out, to deliver two quality products in hydrogen and graphite.

READ: Hazer wants a hydrogen plant running by 2023, foreign interest is already lining up

Why Woodman Point? Waste-water treatment plants produce a s#@t load of biogas, which is either used to generate power and provide process heat to site operations, or simply destroyed through flaring.

Hazer wants to use this waste gas to produce both hydrogen and graphite.

It’s a win all around. Hazer proves the tech works, reduces emissions, increases the value of waste-to-resource recovery, and provides a valuable local source of renewable hydrogen as a transport fuel, industrial feedstock or source of renewable energy.

The potential to use locally produced biogas as a feedstock for the Hazer process is a compelling proposition, says Hazer boss Geoff Ward.

“It offers a combination of low production costs, significant carbon abatement and proximity to future users of hydrogen as a transport fuel in bus fleets, heavy transport fleets and large industrial users, while adding significant value to a waste resource,” he says.

“We believe this first project will be an effective demonstration of the potential for this model to be replicated at larger commercial scale both in Australia and internationally.”

The company wants to kick off detailed design, approval, and early procurement activities by mid-2019, with commissioning of the Hazer owned-and-operated plant to begin at the end of 2020.