You might be interested in

News

Market Highlights: ASX set to rise again, Birkenstock's disappointing IPO, and 5 ASX small caps to watch today

News

Top 10 at 11: A mixed morning for lithium news and graphene is still on the boil

Mining

Tech

Special Report: First Graphene’s new PureGRAPH™ product range is already being put to work, just a few weeks after launching to market.

The advanced materials company (ASX:FGR) today announced a successful commercial application for the newly-released products: improving the protective polymer linings of critical mining equipment.

It demonstrates one of many present-day, high-volume applications for graphene – a promising nanomaterial that can greatly enhance the performance of a wide range of materials, from concrete through to batteries, elastomers, fire retardants paints, polymers and water filtration.

First Graphene says it has been working closely with a number of companies to demonstrate how the addition of its PureGRAPH™ graphene products can enhance other materials.

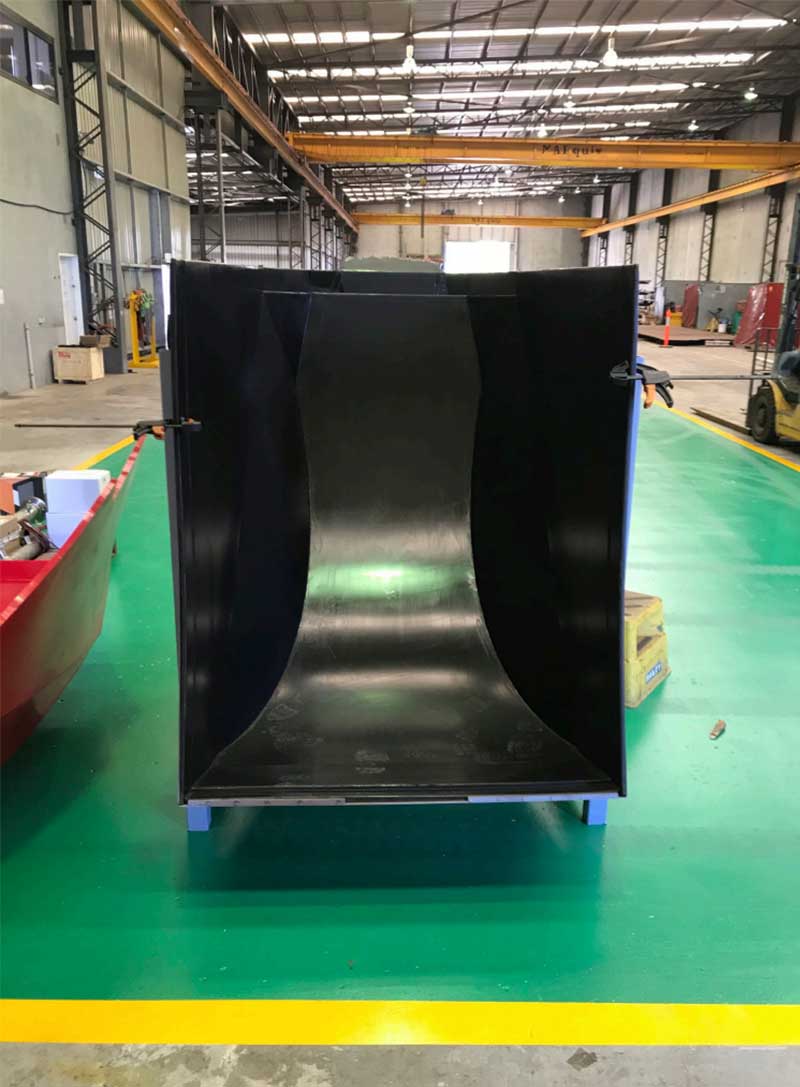

Today, the company told investors how its graphene extended the wear-life of a full-scale mining reclaimer bucket when incorporated into protective polymer linings.

It conducted various tests in conjunction with mining and industry solution provider newGen to determine the specific product and the optimum quantity to be added.

First Graphene has developed three main graphene products – platelets of 5, 10 and 20 microns with very high aspect ratios, which were announced just last month.

The tests confirmed that the PureGRAPH product provided “significantly increased flexural strength to the base polyurethane product.”

Opening the door to new opportunities

First Graphene says the success of the tests was a result of the high consistency of its PureGRAPH™ products and the ease of dispersion into the polymer resin.

newGen have now cast a liner for a Sandvik reclaimer bucket using PureGRAPH™ graphene and plans to cast and sell additional bucket linings for use in northern Australia.

First Graphene managing director Craig McGuckin says it marks the start of an important growth curve for graphene-enhanced rubbers and composites.

“The challenge when it comes to commercialising graphene-based products is twofold: The first is the availability of reliable supply. The other, is the quality of graphene produced.”

“First Graphene is producing high-quality graphene at a very competitive cost following extensive testing and characterisations of the products.”

“We have commercialised this ground breaking, high performance material by offering reliable supply, with proven, real-world applications.”

The company has said its current focus is on fire retardants, super-capacity batteries, composites, polymers, elastomers and concretes, though there are additional applications under investigation.

The company was one of three first-tier partners to be invited to the University of Manchester’s $107 million Graphene Engineering and Innovation Centre (GEIC) that will be officially opened on the 10th of December 2018.

It announced earlier this month it had signed a three-year Memorandum of Understanding (MoU) with the university to supply graphene products for researchers.

First Graphene is a Stockhead advertiser.