Vulcan Energy spills the beans about how it has become a darling in the lithium game

Mining

Mining

Vulcan Energy has been one of the undisputed roaring success stories on the ASX, with shares in the company rising 3,605% since listing at just 20c back in May 2018.

Simply put, if you’d thrown $1,000 into the company’s float, you’d be looking at a profit of more than $35,000 today – a very tidy profit by any standard.

So – what’s the magic recipe that has turned this ASX newcomer into one of most intriguing lithium stories with a market capitalisation testing the $1bn mark in just four short years?

The secret behind Vulcan Energy Resources’ (ASX:VUL) growth is its unique approach to lithium production that neatly captures the zeitgeist of the times – namely the growing awareness of the need to decarbonise ahead of achieving net zero emissions by 2050.

At first glance, the company’s Zero Carbon Lithium™ project in Germany’s Upper Rhine Valley looks like your standard brine project that seeks to produce the valuable battery metal from what is essentially extremely salty water with lithium dissolved in it.

But there is one significant difference – and it is one that makes all the difference.

Speaking to Stockhead, managing director Dr Francis Wedin noted that the lithium brines that the company is targeting are located deep underground, with plenty of renewable heat embodied in the brines.

While the use of this heat to drive the lithium extraction process would rather handily make the project carbon neutral by itself, Vulcan’s project also happens to have an excess of this handy resource.

What this means is that besides producing lithium, the Zero Carbon Lithium™ project will also be capable of producing clean, renewable geothermal energy.

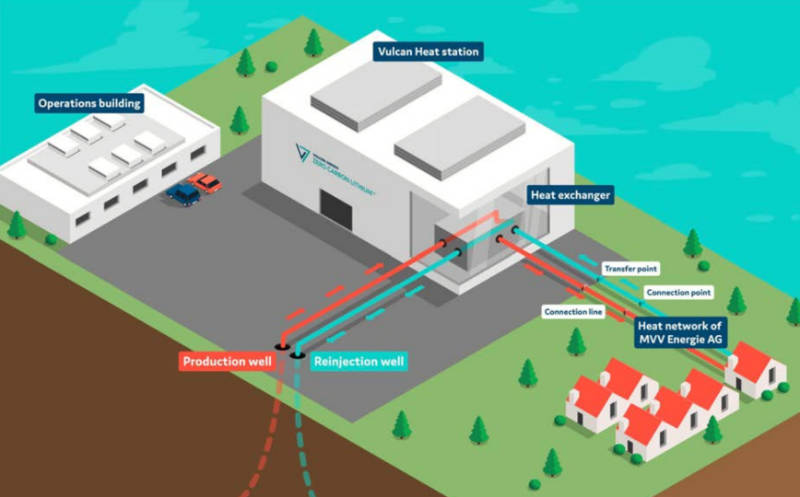

“The idea is that you pump the brine to the surface and you produce energy from it, particularly heating which is very topical in Europe at the moment, and we extract the lithium after that, before reinjecting the brine,” Wedin explained.

“So, we have two saleable products, the energy and the lithium.”

The processes used by Vulcan are further distinguished by the fact that they have all been used separately for many years now.

Brines from the project are pumped out at more than 160 degrees centigrade, and used to produce both electricity and heating through well-understood geothermal processes.

Once the brines cool to about 80 degrees, they are drawn off and passed through the sorption columns where the heat drives the – again – well-known physical and chemical processes to strip lithium chloride from the brines.

The sorption process has been used elsewhere commercially since 1996, including in Argentina to produce lithium from brines.

The process also benefits from not requiring any acid or base reagents during the stripping process, which reinforces the clean nature of Vulcan’s project.

Once this is completed, the remaining water is reinjected into the brine reservoir while the lithium chloride concentrate is further concentrated, using steam generated from the geothermal component to force the evaporation process.

The lithium chloride concentrate is then sent through green energy powered electrolysis that uses an electric current to produce lithium hydroxide – a key battery chemical used in the production of lithium-ion batteries.

“We have secured a spot at the Höchst Chemical Park just outside of Frankfurt. There, we are collaborating with a chemicals company called Nobian, who are experts in operating this kind of plant, which is similar to plants used in the chlor-alkali industry,” Wedin noted.

He reiterated that none of the processes are new technologies on their own.

“That’s very critical, it’s not like an R&D project, of course there’s optimisation for our particular brine that we need to do but it is adapting and combining existing processes,” Wedin said.

Vulcan has been pushing hard on its Zero Carbon Lithium™ development, building up a team of 120 people split between its geothermal and lithium business divisions.

This has ensured that all of the company’s intellectual property and equipment is in-house, allowing it to build a one stop shop to produce renewable energy and zero carbon lithium.

“On the geothermal side, we have an operational, commercial geothermal power plant with wells already producing from the Upper Rhine Valley brine fields,” Wedin noted.

“We have also defined what is Europe’s largest lithium resource and have built a pilot plant that has been operating for a year now demonstrating the extraction process.”

This is significant progress for a company that was listed just four years ago but Vulcan is already pressing ahead.

“On the heat side, we are making a lot of progress there, we are selling renewable power into the grid but we also want to sell heating. This is because geothermal is uniquely positioned to decarbonise heating,” Wedin noted.

The company also has two oil and gas rigs that have been repurposed for geothermal that it intends to keep busy over the next 10 years, drilling geothermal wells.

Vulcan is also keen to expand its lithium resource and project pipeline with Wedin pointing out that its current resource calculation of 15.85 million tonnes of lithium carbonate equivalent is based on just three of its 11 licences.

“We are also in discussions with strategic investors to invest alongside us on the projects where they can add some technical or other types of value coming to the project, so not just the cash investment but being aligned,” he added.

“That could also be a major catalyst and accelerant for the company.”

Vulcan’s plan to produce lithium with a net zero carbon footprint in the heart of Europe has not gone unnoticed by the biggest consumers in the sub-continent.

The company has signed up five different consumers of lithium for binding lithium hydroxide offtakes in Europe.

These are Volkswagen – the largest company in Germany, Renault, Stellantis – one of the largest car groups in the world that covers Fiat, Chrysler and Citroen, LG Energy Solution and Umicore Group – a leader in cathode materials production.

“We are basically fully sold out for the first five years of production and that’s very important for financing this project,” Wedin explained, adding that its success with European automakers was due to producing a product that they really want in terms of sustainability and supply security.

Europe’s reliance on Russian gas has also made Vulcan’s geothermal plans extremely attractive with the company recently reaching a binding agreement with Germany’s largest municipal energy supplier MVV to supply the city of Mannheim with renewable heat, starting in 2025.

“And we plan to execute many more contracts of this type, so we are building up the renewable energy side, we are building up the lithium side, aiming to get into commercial production for lithium in late 2024 and scaling up from there in 2025 and beyond,” Wedin said.

“On the renewable energy side, we are already in commercial production but we aim to scale that up as quickly as possible.”

Taken together, Wedin believes that his team has designed a company that has been designed from ground up not just to be zero fossil fuels and zero carbon, but rather into a “decarbonisation impact investment stock”.

“It is really the first of its kind in the world, not just in lithium but any raw materials, really,” he noted.

“But in doing so, according to our feasibility studies, we show a very profitable business model as well, including a very low cost of operation because we are using that heat embodied within the brine.”

Both lithium and renewable energy are in high demand and the company is keen to capitalise on this.

Over the next 12 months, Vulcan plans to complete its Phase One DFS in the second half of this year.

“We are also constructing a demonstration plant, which will essentially be an operational training tool for our team. We think it will be a catalyst once it enters into production in the second half of this year,” Wedin added.

The company will also work on a revised PFS for a much larger Phase Two development due to the strong demand from customers to grow the project.

This article was developed in collaboration with Vulcan Energy Resources, a Stockhead advertiser at the time of publishing.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.