Strike’s detrital material could yield low-cost, high-grade iron ore

Mining

Mining

Special Report: Strike Resources has unearthed a potential new source of low cost yet high-grade iron ore at its Paulsens East project in WA.

This comes after recent earthworks identified high-grade hematite rich detrital material at surface that has not been previously accounted for in the company’s resource inventory.

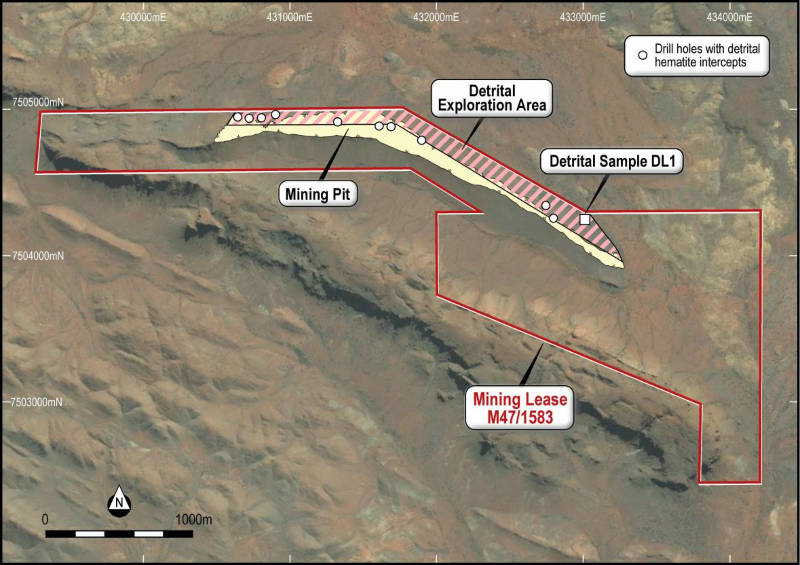

Strike Resources’ (ASX:SRK) current resource for Paulsens East comprises a 3km long outcropping hematite ridge hosting 9.6 million tonnes grading 61.6 per cent iron.

Laboratory testing of samples taken from surface to a depth of 1.5m from a site located about 100m north from the base of the ridge resulted in a product grading 60 per cent iron along with a mass recovery of 83 per cent from crushing to 32mm and simple wet screening at +1mm size.

Visual inspection of the sample location indicated that the eroded detrital material extended to at least 1.5m depth.

Additionally, a review of drill logs from the company’s previous drilling along the northern edge of the hematite ridge has confirmed that a number of drill holes encountered iron rich loose scree within the first few metres from surface.

“The presence of such high-grade detrital material is very exciting,” managing director William Johnson said.

“If the existence of significant quantities of this iron ore material are determined as a result of the current exploration program, such material has the potential to deliver additional value for Strike which has not previously been accounted for in our project studies.”

Strike recently secured an initial 21-year mining lease over Paulsens East after executing a Native Title Mining Agreement.

Detrital iron ore deposits are formed by weathering and erosion of outcropping iron mineralisation, with such eroded material often being found at the base of outcropping ridges of mineralised rock as pebbles and fine gravel mixed with soil and alluvium.

Notable examples of successful detrital mining in WA include Mt Newman and Brockman 2 Detritals Mine.

The company says mining and upgrading these types of deposits involves simple excavation using bulldozers and front-end loaders before subjecting the material to minor crushing along with relatively inexpensive dry or wet screening.

As detrital material is already broken and reduced in size, strip ratios are generally very low and no drilling or blasting is required, which could substantially reduce costs compared to mining normal bedrock material.

Strike plans to test the potential extent and quality of the detrital material at Paulsens East with a sampling program of up to 120 pits to be dug over an area of about 2,700m long from east to west by widths of 100m to 150m from north to south.

The pits will be dug up to 3m in depth (or until visual mineralisation ceases to be observed) and located mostly on existing tracks and cleared drill pads.

Notably, the area being investigated sits partially over the area of the open pit designed for the proposed main Paulsens East mine.

This surface material was previously intended to be cleared as waste as the main project was developed.

Samples taken from the pits will be sent for test work and analysis to determine the iron grade, impurities and the best manner for the detrital material to be upgraded to a DSO product.

If the exploration program confirms the presence of significant quantities of detrital iron ore, the company will undertake further studies to determine the commercial viability of exploiting these detrital materials.

This article does not constitute financial product advice. You should consider obtaining independent advice before making any financial decisions.