You might be interested in

Mining

AVL cuts the ribbon on brand new vanadium electrolyte manufacturing facility

Mining

Monsters of Rock: Could this logical merger finally get Australia's vanadium sector off the ground?

Mining

Mining

Special Report: Australian Vanadium may have increased the mine life at its namesake project in Western Australia after doubling the high-grade indicated resource.

Resource upgrades are always a positive for mineral projects as they provide the potential to improve both the economics and productive life of the project in question.

So Australian Vanadium (ASX:AVL) could be forgiven for feeling a little excited after upgrading the indicated resource of the distinct high-grade magnetite zone at its project by 115 per cent to 25.1 million tonnes (mt) grading 1.1 per cent vanadium pentoxide (V2O5).

Indicated resources have enough grade continuity and geological certainty behind them to support mine planning, which could support an increase to the forecast 17 year mine life forecast that the company had estimated in its pre-feasibility study.

It is also notable given that most vanadium deposits typically contain between 0.2 per cent and 1 per cent V2O5.

The high-grade zone also includes a measured resource of 10.1mt at 1.14 per cent V2O5 and an inferred resource of 52.7mt at 1.04 per cent V2O5.

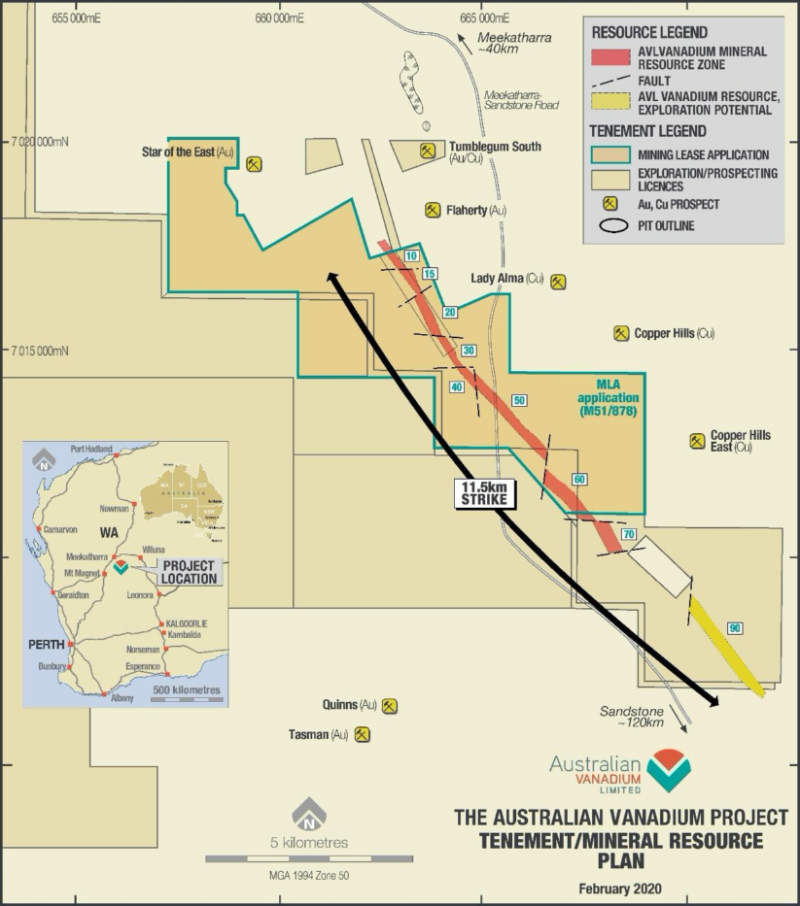

Total resources at the project have increased by 9.5 per cent to 208.2Mt at 0.74 per cent V2O5. The deposit remains open at depth and there is still potential to shift further inferred resources along its 11.5km strike length into the measured and indicated categories.

Australian Vanadium says the successful conversion of 13mt of existing high-grade resource from inferred to the higher confidence indicated category strongly supports the company’s ongoing optimisation studies to extend the life of mine.

Additionally, detailed magnetic susceptibility analysis has outlined the opportunity for improved vanadium recovery.

These are all welcome developments given that annual global vanadium consumption is expected to grow to more than 135,000 metric tonnes by 2025 while demand for vanadium in batteries expected to grow to 25,000 metric tonnes by 2020.

The Australian Vanadium project is expected to produce 5,700 metric tonnes of vanadium per annum.

“In discussions with potential funding and joint venture partners, a de-risked and large resource base has been a key requisite,” managing director Vincent Algar said.

“The new indicated resources successfully targeted known higher magnetic areas which will benefit the mine planning, adding flexibility to the schedule.

“Flexibility will ensure feed and concentrate specifications are optimal for the Australian Vanadium project’s process, enabling the recovery of high purity vanadium products.”

Algar added that the increase in both the indicated and total resource tonnages gave the company a project comparable to operating producers such as Largo Resources and Bushveld Minerals.

Mine optimisation studies have started to incorporate the new indicated resource into a mine plan.

Algar is presenting at the WA Major Projects Conference today at the Perth Convention and Exhibition Centre.

Last month, the company’s laboratory test work to simulate the industry standard Grate Kiln process resulted in improved vanadium extraction averaging about 92 per cent compared to traditional rotary kiln extraction of between 85 to 88 per cent.

This was due to pelletising the concentrate produced by preliminary beneficiation, which resulted in higher reaction progress, greatly reduced kiln build-up, significant reduction in dust loss and ease of process control and heat recovery.