Infinity hits key milestones at San José lithium hydroxide project as EV boom approaches

Mining

Mining

Special Report: Infinity Lithium is ticking all the boxes as a pre-feasibility study (PFS) on the world-class San José lithium hydroxide project in Spain nears completion.

2020/21 is likely the tipping point where “timid growth” ends and EVs become mainstream in Europe, according to new data.

EU carmakers will be offering 214 electric models in 2021 – up from the 60 available at the end of 2018.

If everything goes according to plan, 22 per cent of vehicles rolling off European production lines could have a plug by 2022.

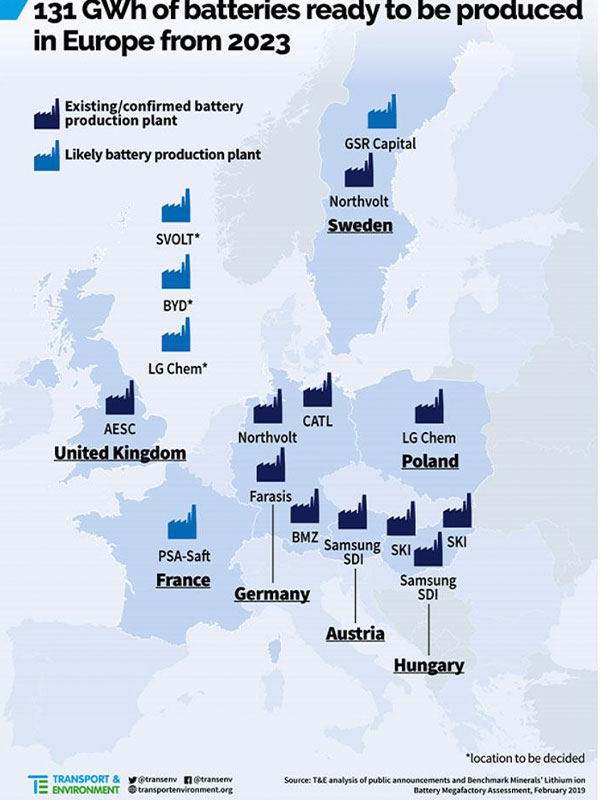

To meet this goal, there are 16 large-scale lithium-ion battery cell plants confirmed or likely to come online in Europe by 2023, according to Benchmark Mineral Intelligence data.

But the EU is also committed to developing its own raw material production.

Access to locally sourced lithium chemicals will be a big part of this plan, which puts advanced explorers like Infinity Lithium (ASX:INF) in a great spot going forward.

Currently, Infinity is successfully testing an environmentally friendly and cost-effective lithium hydroxide process.

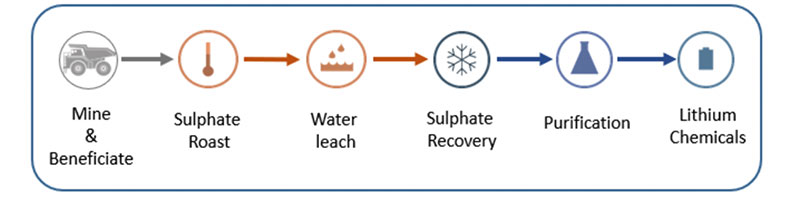

As part of the ongoing PFS, Infinity is using a sulphate roasting and water leach process which removes the need to use large volumes of environmentally damaging sulphuric acid.

And the near-term producer expects to recycle about 85 per cent of the main reagent potassium sulphate – which means minimal ‘top up’ through the production cycle.

Infinity have gone about testing its process extensively and methodically from start to finish, says managing director Ryan Parkin.

“After a plant stage 1 update and Stage 2 update in Q2, this final stage was around producing lithium hydroxide using beneficiated and post-roast water leach material,” Parkin told Stockhead.

“Our first indication is that it’s a better outcome for the project as a whole,” he says.

“And it’s a substantial improvement environmentally, in terms of our potassium sulphate usage and our tailings profile.”

This enhances the project’s environmental credentials compared to its hard rock peers, an important consideration as the EU’s automotive industry focuses heavily on both the carbon footprint and sustainability considerations as diesel vehicles are phased out.

Infinity is now undertaking additional testing using that recycled material to produce lithium hydroxide, managing director Ryan Parkin says.

What are the next steps?

Infinity is pushing ahead “very heavily” to complete this PFS ahead of more serious discussions with financiers and offtake partners.

“We’ve already been engaged in long standing negotiations with OEMs – essentially automobile manufacturers and cathode producers within Europe,” Parkin says.

“These companies are trying to lock in their raw material requirements moving forwards to 2023-2025, when their EV production is expected to increase at a significant rate.

“They are starting to move quickly now to secure supply, because without those raw materials and in particular refined lithium chemicals, there are no electric vehicles.”