Nanollose says its waste-based clothing technology can now be rolled out en masse

Tech

Tech

Eco-clothing maker Nanollose has now made its first clothes using fibre converted from waste products.

But it’s still not making any money.

In its quarterly update this morning, the company announced another round of R&D agreements and but no commercialisation plans yet.

Show me the money

Nanollose (AX:NC6) is looking at developing its global supply chain and launching a pilot scale-up of clothing production using its fibre technology.

Over the next three to six months, the company wants to offer its current stockpile of microbial cellulose — around 250kg — for use in “limited edition” rollouts by existing clothing manufacturers.

But at this stage the December quarterly financials are still drawing a blank in a key row: “cash receipts from customers”.

The company is spending most of its cash on R&D but over the last 12 months has also slowly lifted its marketing spend as they for commercial deals for eco-fabrics.

Spending was in the red by $484,000 and forecast spending for this quarter is almost $600,000.

The company has been slowly drawing down on the $5 million raised during the 2017 IPO; it started 2018 with $3.8m and finished with $2m.

On current trends, the company’s liquidity will be getting seriously tight if it doesn’t source a cashflow injection before the end of the year.

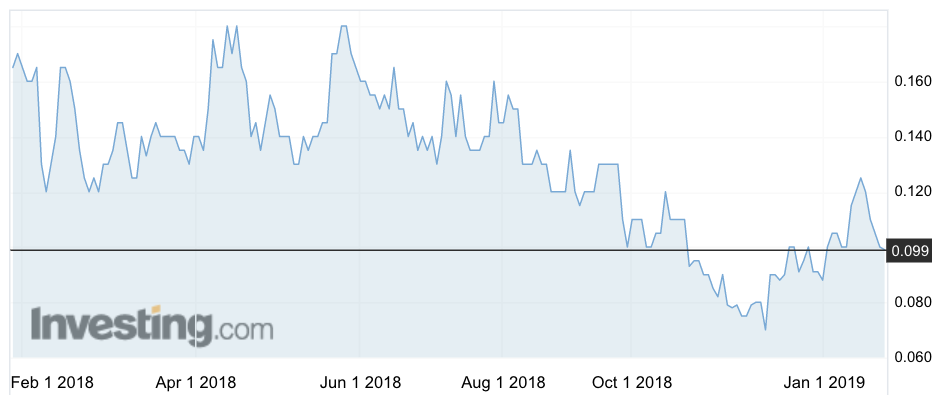

The company’s stock was flat at 9.9c after the quarterly report was released.

Tree-free

After making a test garment using its Nullabor fibre technology last October, Nanollose’s (AX:NC6) big news in December was that it now has the real deal: a sweater made with 3D technology.

Nanollose said the fibre held up well during the industrial manufacturing process, a key factor in its viability for use in large-scale clothing production.

That’s good news for an industry “urgently seeking sustainable alternatives” to rayon and cotton processes, which require the chopping down of 150 million trees annually.

While the company jumped into the headlines by making cloth fibres out of beer waste, the test sweater was created out of coconut waste sourced from Indonesia.

Nanollose also secured an agreement in November with Indonesian food producer PT Supra Natami Utama as it eyes a scale-up to commercial production.

The company says it will source up to five tonnes of microbial cellulose from PT Supra Natami Utama by the end of the year.

“This will enable Nanollose to provide small commercial quantities of Nullarbor fibre to selected clothing brands to commence its introduction into their collections and product offerings,” the company said.

Stockhead is seeking comment from Nanollose.