Aussie scientists have discovered an effective way to recycle rare earths metals

Tech

Tech

Right now, we have no effective method of recycling rare earths metals (or REMs), an essential ingredient in mobile phones and hybrid-electric cars.

A dismal 3 to 7 per cent of REMs are recycled from end-products because current processes are uneconomic and/or generate huge amounts of toxic waste.

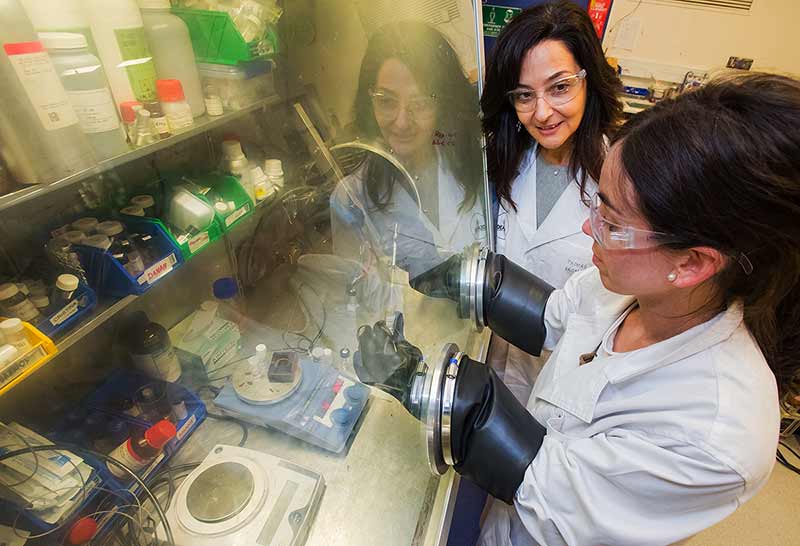

It’s early days, but scientists at Deakin University and Spain’s Tecnalia research and innovation hub may have found a solution.

After separating the metals from your old phone, they would use ionic liquids (liquid salt-based systems) to recover REMs from the resulting solution using a low electric current.

Deakin Institute for Frontier Materials (IFM) researcher Dr Cristina Pozo-Gonzalo leads the project.

She says increased demand for REMs – which include elements like cerium, praseodymium, neodymium, and lanthanum – is creating pressure on global supply chains.

“To add to concerns, almost 85 per cent of the world’s REM primary resources are in China, where their government has restricted exports for periods of time in the recent past, endangering availability and price stability,” Dr Pozo-Gonzalo says.

“There’s growing concern that future access to these materials won’t be reliable, leading to them being targeted for reclamation and recycling.”

This new method for recovering REMs has “great potential” and minimises the generation of toxic and harmful waste, Dr Pozo-Gonzalo says.

“We are also aiming for a method that can easily be implemented widely across the world,” she says.

“Our work addresses a key knowledge gap in the REM recycling process.

“It is an important early step towards establishing a clean and sustainable processing route for REMs and alleviating the current pressures on these critical elements.”

READ: High Voltage — Spodumene prices ‘nothing to complain about’, says Pilbara Minerals boss

This research report reckons demand for critical metals like lithium, cobalt and rare earths could exceed reserves under a 100 per cent renewable energy scenario – which will make effective recycling crucial.

But let’s look at lithium for a second. The problem with many current battery recycling methods is the lithium is destroyed during the process.

Luckily there’s companies like Lithium Australia (ASX:LIT) and Neometals (ASX:NMT) which have developed processes that recover all of the materials from old batteries, including the lithium.

In February, Perth-based battery tech company Neometals fired up its lithium-ion battery recycling pilot plant in Canada.

The company says it has developed a profitable process that recovers 90 per cent of all raw battery materials, like cobalt, manganese, nickel and lithium from used batteries.

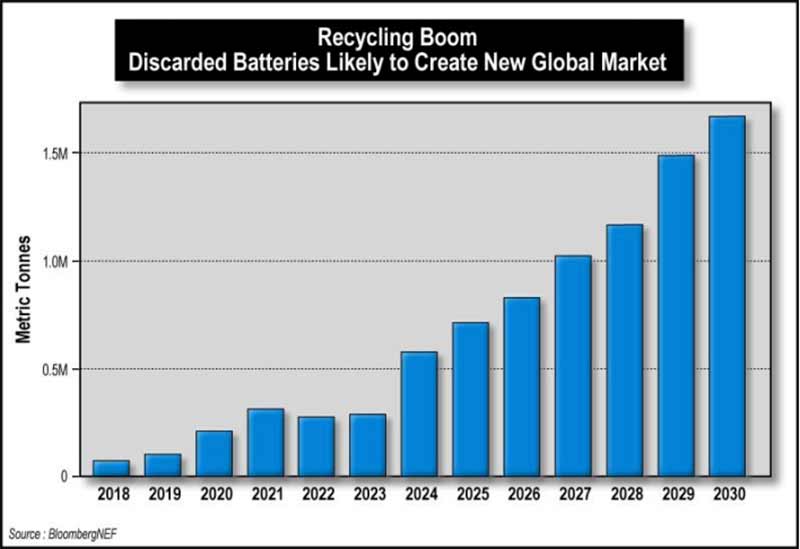

Neometals boss Chris Reed told Stockhead at the time that the recycling sector needs to get a move on.

“The volumes of car batteries that are being produced are increasing quickly and the numbers coming back [for recycling] are bigger than we had planned,” he says.